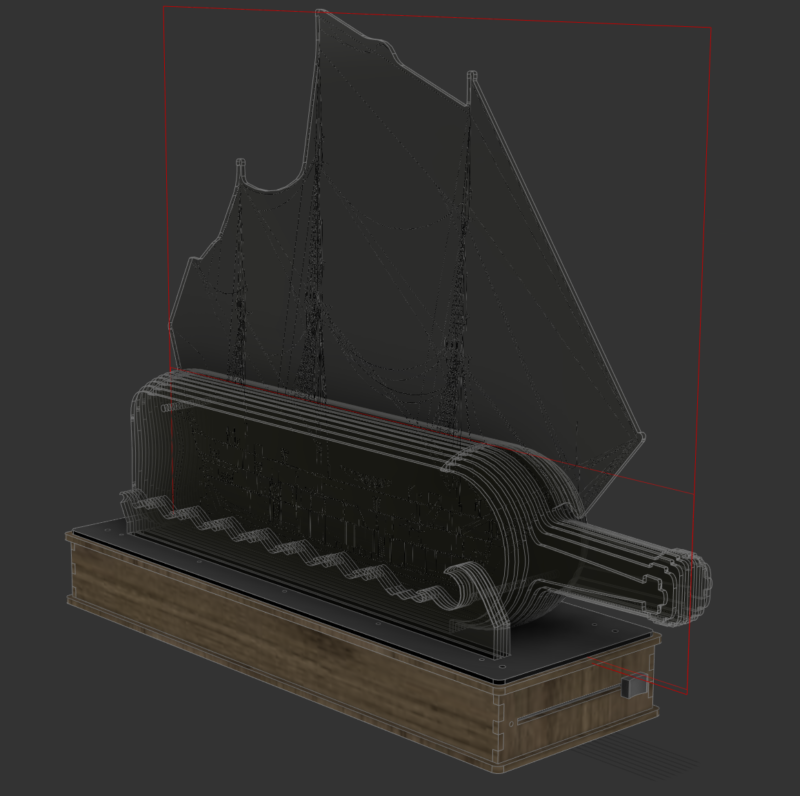

My biggest failure this week was not ordering parts sooner. I already received most of the electronics, but I was still missing all of the acrylic and wood I needed to start laser cutting. Instead, I finalized the CAD model for the base. I decided to laser cut the base instead of making it by hand, just to simplify the process of making it. What I came up with is pretty plain looking, but I think it will be functional and not distracting.

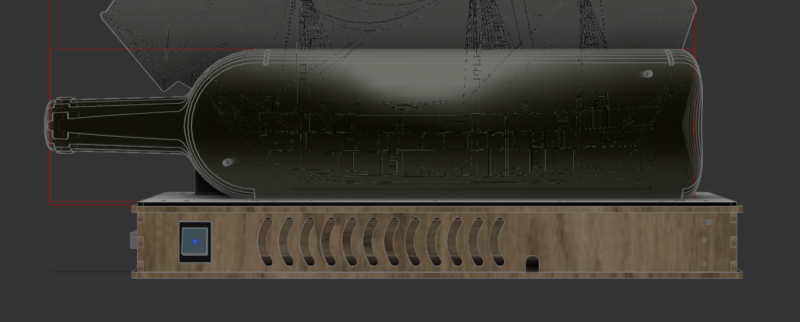

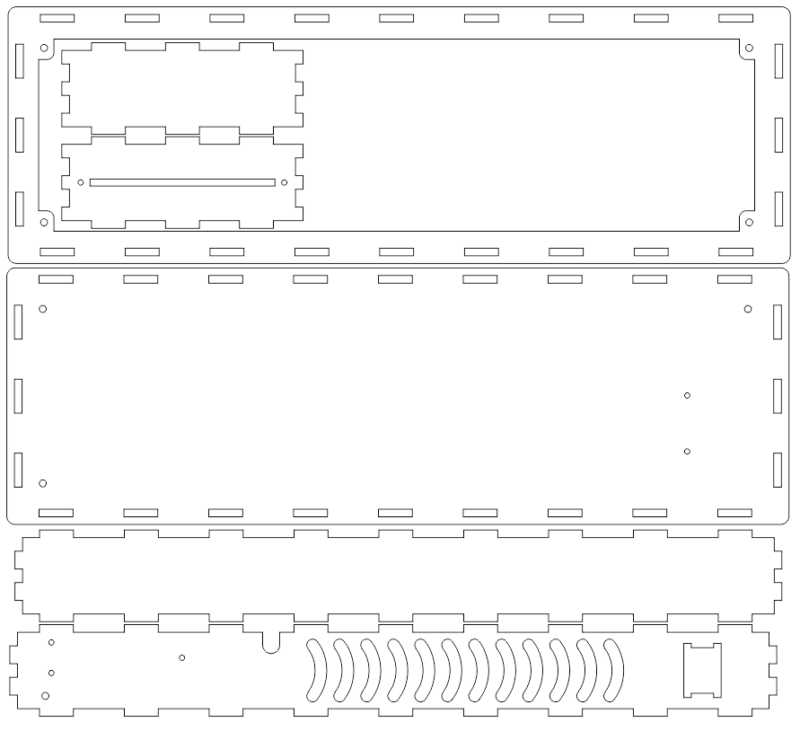

I also added the slider to the front, switch on the back, and some vent holes:

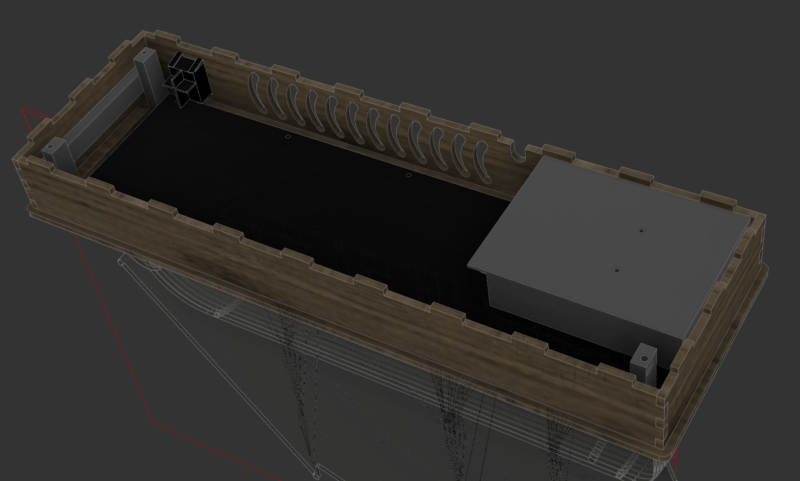

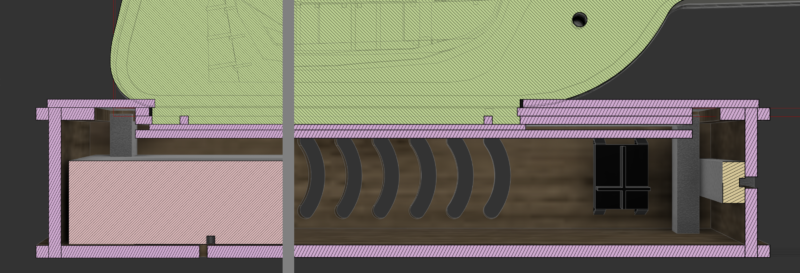

I modelled the power supply and made holes for M3 screws to mount it. I also added some 3D printed components with captive nuts so that I could screw the top and bottom together.

In order to keep the acrylic sheets from coming out, I added a notch in the layers. By offsetting the layers slightly, the acrylic can slide in. Then you line the layers up which fits the black layers into the notches in the clear acrylic. The screws hold the layers in this position.

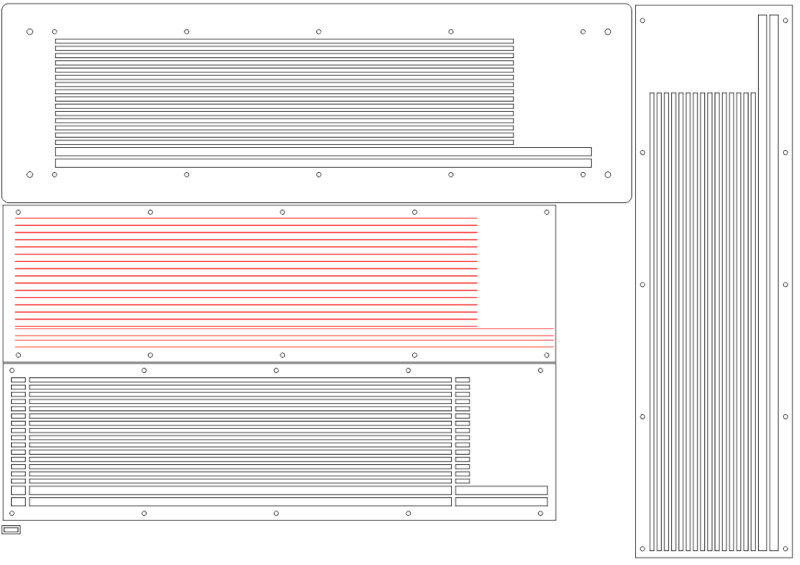

I’m going to laser cut the base on Wednesday, so I laid out the black acrylic sheet and wood sheet.