In the late Spring of 2016, I was greatly inspired by Clair Danes’ dress at the Met Gala. The Met Gala is one of the largest events to take over the internet every year as all A-List celebrities attend in their best couture looks by top designers. The theme was “Manus x Machina: Fashion in an Age of Technology” and she made a statement with a dress so high tech, yet so elegant. The designer of the gown is Zac Posen. He created the look by threading small fiberoptic cables into organza fabric. Since high school, I was very intrigued by how technology can be infused into fashion, and how I could be a part of the moment. I decided to choose a fashion light art tech project to help me explore the possibilities.

The concept behind this dress pushed me to ponder: “how could fiber optics be added in everyday clothing”. I figured that denim would be easy to weave through and sturdy enough to hold the cables in a place like the organza fabric used on this gown, so I developed the idea of creating a pair of jeans with fiber-optics.

Since I was new to fiber optic cables, it was important for me to attain a general understanding of how they work. I started with a kit that allowed me to test out various sizes, colors, thicknesses. My primary focus was testing flexibility and light bending capabilities. I gravitated towards the 0.2 cm cables because they were the most bendable, easy to thread through the denim, and a lot of them could make a large statement.

After selecting the cable, it was important to select how the optic cables would weave through the jeans. I tried an over-under technique that was close together and far apart and an on top approach. It helped that the jeans were thin enough and the cables were sturdy enough for me to weave them through the jeans like a thread. I decided to go with the over-under weaving option with a general spacing between because it would make them more secure in the jeans and create some form of uniformity.

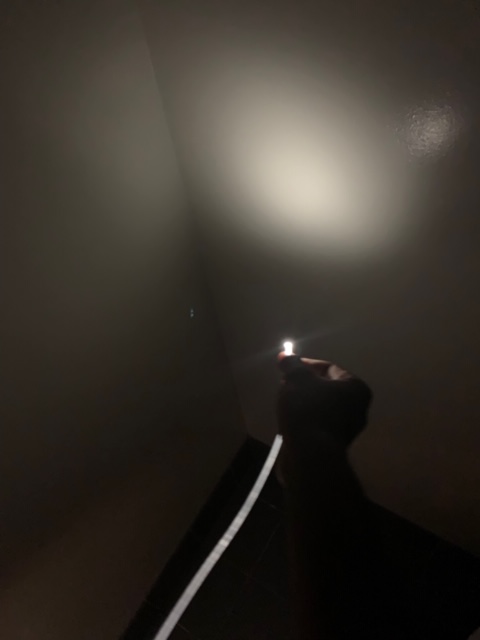

Once the cables were separated, I had to decide how they would be connected to the LED. I tried sticking them straight out from the center but that was useless since the cables needed to be pointed downwards. I noticed that cutting a small slit at the bottom of the LED would hold them long enough to add the glue and for the glue to dry. This leased to my next question: which glue was the best glue to bind silicon and PMMA (the material that fiber optics are made with)? I tried gorilla glue, plastic epoxy, quick set epoxy, and a silicone adhesive. I desired to go with the quick epoxy because it dried the fastest and held the cables the best without allowing any to slide through whenever pulled and dried clear so that the reflection and transfer of light through the cables wouldn’t be interfered with.

While putting the pants together, I encountered various challenger, primarily with the battery and adhesive used to connect the cables. Initially, I planned to use a small portable charger with a USB port that would sit in the pocket of the jeans. After testing out three charger sizes, they were inconvenient and not seamless, so I researched a smaller option. After doing some calculations and browsing the web, I purchased a power booster that takes in 3.7V from a Lipov Battery Rechargeable Lithium Polymer and outputs 5V to power low direct current devices. At first the charger was not working, and the battery could not power it. After troubleshooting, I realized that the input was switched between positive and negative, so I had to pull it apart and Sauter them back together. Then, the lights pulled too much current causing it to heat up very fast and discharge the battery in a matter of 3 minutes. After charging the lipo battery fully and shortening the LED strip, I no longer had to worry about the battery overheating or dying fast and it fit very smoothly to the jeans, going completely unnoticeable.

Properly securing the fiber optic cables to the LEDs was one of the most critical and complex parts of this project. The gorilla glue was yellow and hardened but the cables were able to skip through the air pockets created. I ordered plastic epoxy but it dried a gel texture that the cables could easily slide through and be pulled off, and the color was tan which interfered with the flow of light through the cables. After doing more in-depth research, I decided to go to Home Depot and pick up an extra-strength quick epoxy and a silicone adhesive. After testing both of them and allowing them to dry for 20 hours, the cables pulled right out of the silicone adhesive, but they were secure under a good amount of force with the quick epoxy. To better ensure the cables stayed in place, I added more epoxy when I put them on the waistband of the jeans, and then applied a black felt adhesive on top and let sit for a while to dry.

Overall, I thoroughly enjoy this project. I haven’t felt such bliss in working on something I enjoy in a while, especially with fashion, so it was nice to sidestep and do something different with engineering for a change. Throughout the project, I started brainstorming other ideas for fashion tech pieces I could create in my spare time. Who knows, I could possibly start a side business selling tech-infused fashion or work under a major designer for their new collection.

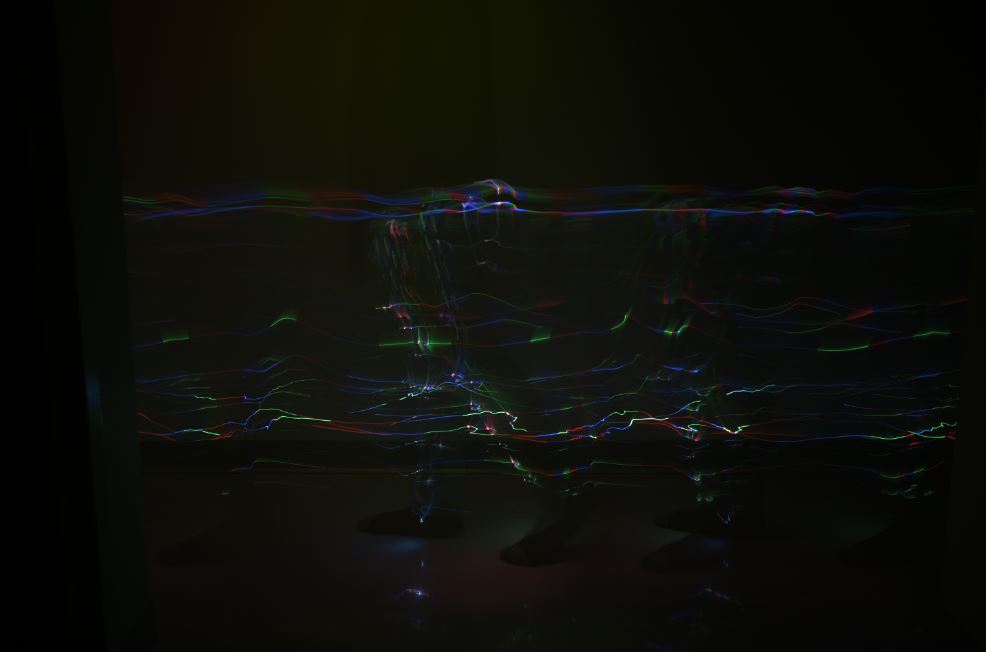

In the mix of taking photos for documentation, I had to seize the opportunity of taking long exposure photos with these pants on. I tested out different exposure times and different movements to get a variety of different photos, and I think they turned out very cool.