This week I went head on against the main areas of my project, that being, laser cutting the actual mirror and wiring the neopixels.

I drew up my final design in Photoshop, and created a vector out of it in Illustrator, so I would be able to laser cut it.

The electrical side of this project has proven to be much more daunting than originally expected. The week started off with me soldering the boards together, which was the first time I had ever soldered anything, so I had my friends give me a quick tutorial. I was starting to get the hang of it, before realizing I still had to solder in the output pins, and couldn’t do so with the boards stacked already, so I had to disconnect everything and start again.

I have still not been able to get the wifi arduino to actually connect to the internet, and ordered an Ethernet one to try a direct connection.

I have set up my color scale and how the temperatures will correspond to colors, and I should have the temperature for 3 days in Worcester being stored in an Array but haven’t been able to test until i can connect to the internet.

Next, I wired a power supply, began preparing the data connections for the lights, but accidentally used a 20 volt power supply and completely fried my LED strip. A new one will be arriving later today. I have already created the proper 5 Volt power supply

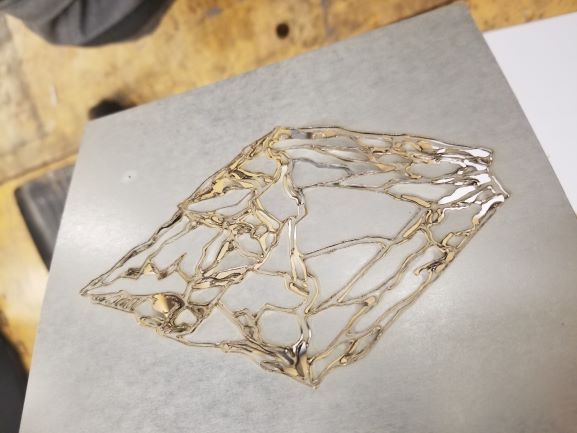

The laser cutting was also much more fragile than I anticipated. I used my thin acrylic mirrors to do test prints to see exactly what effect I am going for and ho to achieve it. The first test, we had the laser too wide and powerful, so the mirror just melted in giant holes. Next we reduced the power and made the width of the beam 1 millimeter, but it was still too strong and melted the mirror too much. For a different pace and proof of concept, I switched to wood, and that was able to cut fine so we could see how the design would appear, however all the tiny pieces began to fall out of once everything is cut and separated. At this point we brainstormed how to proceed. We decided to set the laser cutter to the setting of the thinnest construction paper available, and drop the laser to the smallest and lowest power setting. We then had it make 3 passes of the mirror, slowly etching and barely cutting through. The results came out perfect.

I purchased a 18*24 mirror, and will do the final print using this same technique later this week.

Overall my goal this week is to do the final mirror cut, and set up the lighting encasement first. Then as a test will use regular LED light strips, that do not require extra wiring or setup, because i’m not sure if I will be able to get the whole IoT functionality, and would rather focus on the appearance first.