Hardest Part of Project

For my project, I knew initially the type of design I wanted. But in general the biggest issue I’ve run into is a lack of experience. So I’ve been trying to get insight before I start something I haven’t tried before. The hardest part of my project was going to be designing the enclosure.

Failures

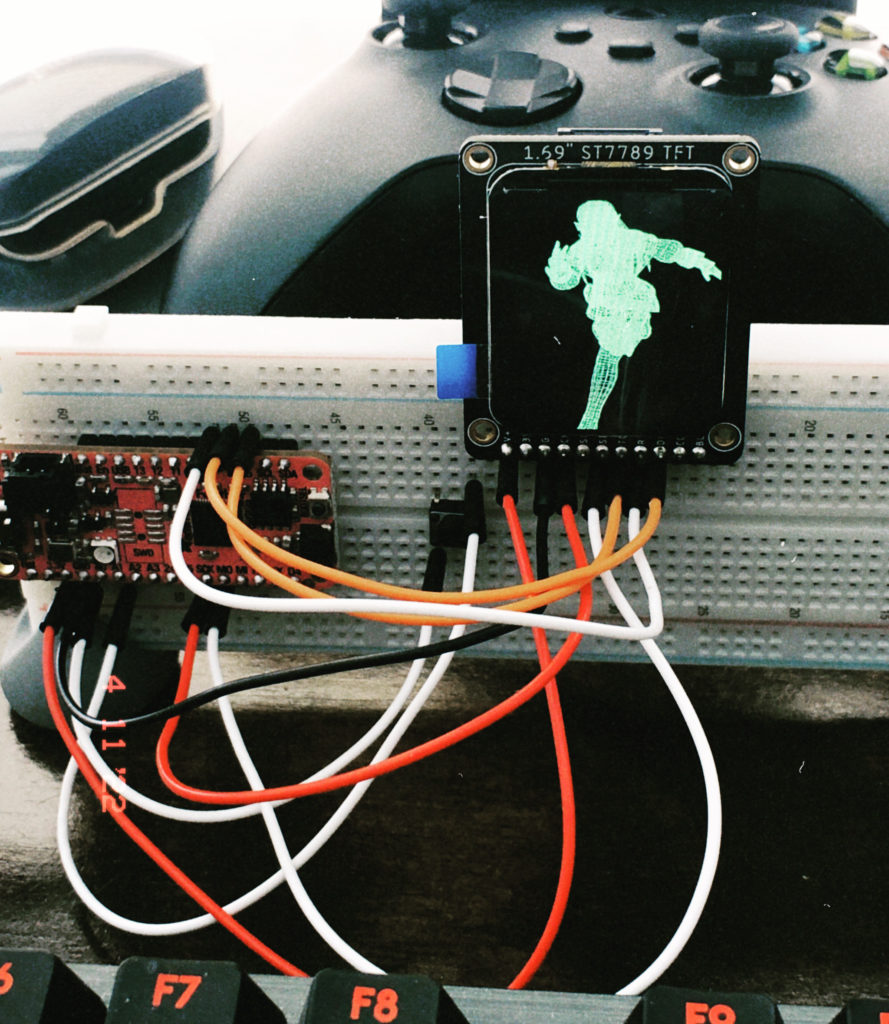

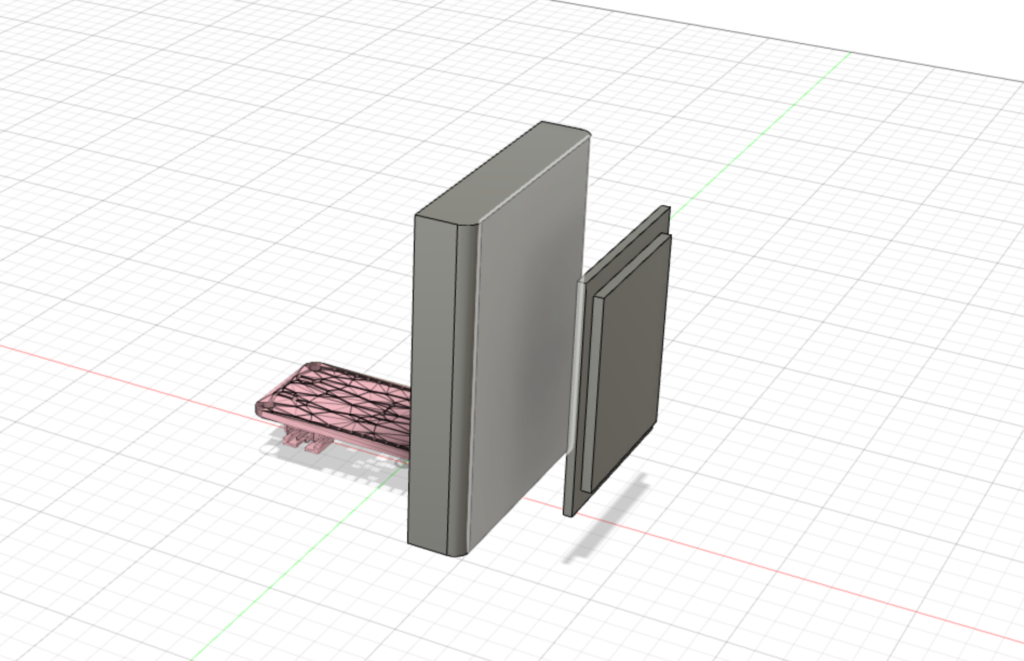

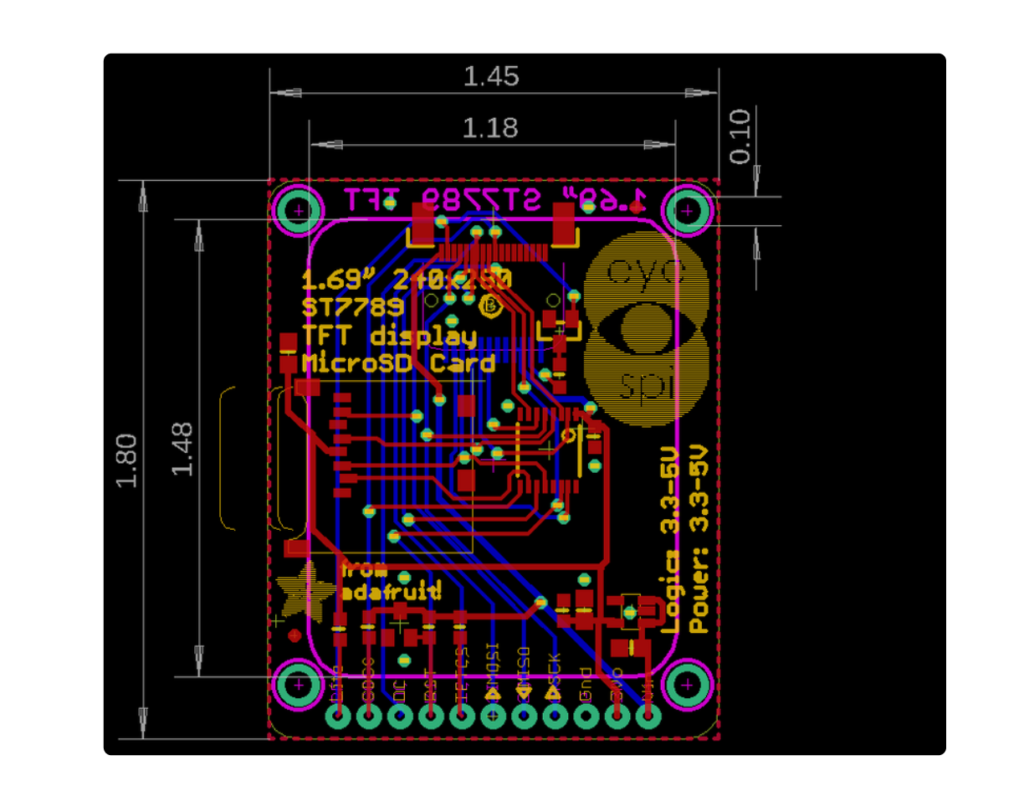

I initially wanted to make a plastic enclosure for the electronics that would conceal them. I created designs of how the parts would fit together considering how 3D printing works. I was able to find an STL file for the board and documentation on the IPS display so I could model the features to fit the components inside.

However, when it came to modeling the parts in Fusion I just had a hard time with it. I’m not familiar enough with CAD yet to create what I want and learning how to use the program was eating up a lot of my time. I needed a faster solution. In addition to this general problem, the wires I ordered online were not what I expected.

Solution 2

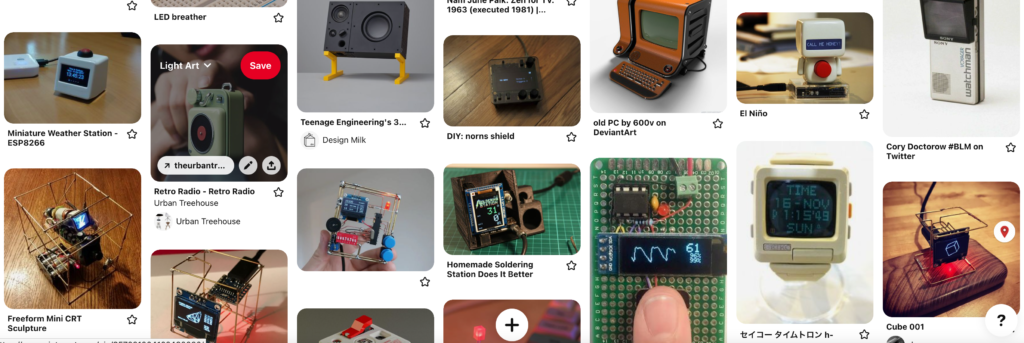

While collecting reference for my project I created an inspiration board made up of any images that I liked. I realized I had potential alternate design ideas on my image board so I looked through them.

Some images were not enclosed at all. Components were held together by the wire that connected them in a sculpture. This seemed like a perfect alternative. It was fast, I wouldn’t have to worry about print times, so I could get instant feedback if something wasn’t working and I wouldn’t have to buy electrical wires at all, because the same wire could be used to connect the components as well as make the three-dimensional structure.

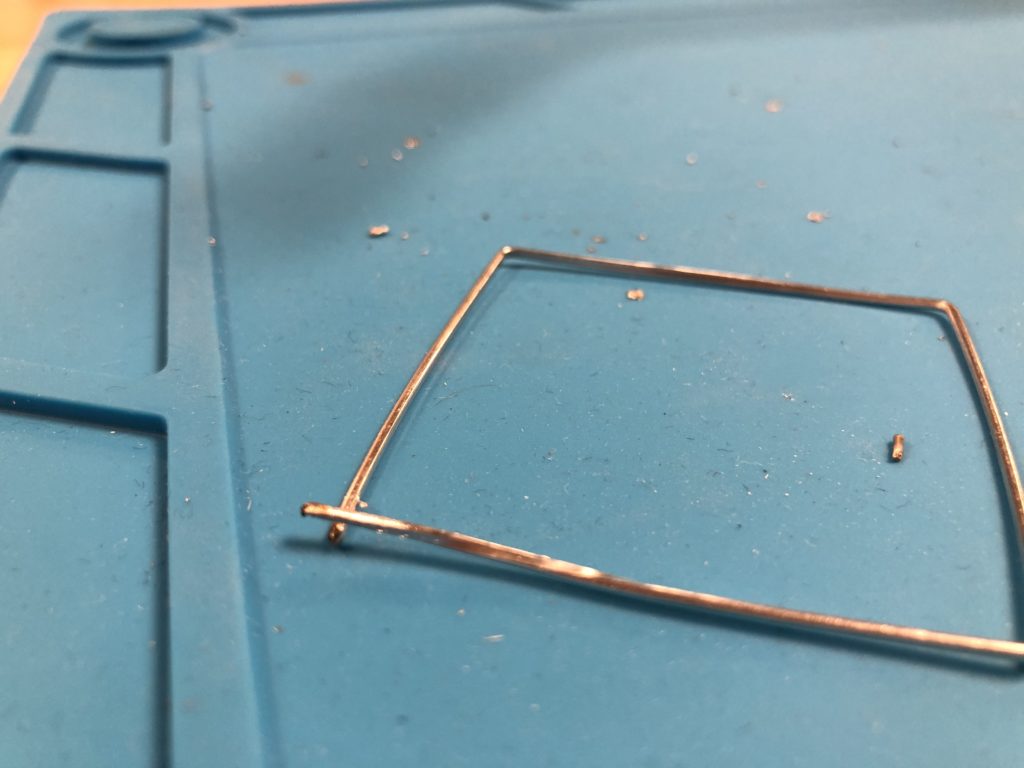

So I got the only wire I had, which happened to be aluminum armature wire, learned how people fabricate sculptures using pipes and wires but realized that they used brass. I wasn’t sure if aluminum was going to work so I did some research on it and followed instructions the best I could. Unfortunately the solder didn’t bond to the aluminum.

I went back to my apartment and learned more about why that was the case. Apparently theres more to soldering than I thought. For aluminum in particular, the wires need to be hot enough to accept the solder and you need to make sure you have the correct type of solder.

https://www.indium.com/blog/soldering-to-aluminum-1.php

I learning what I was trying to make was called a circuit sculpture and they tend to be made of brass so I asked my parents to pick some up at the RISD store. I’m planning to reattempt this project over the weekend.