Hello, I definitely did not get as much progress as I would have liked this week because MQP was not doing so well 🙁

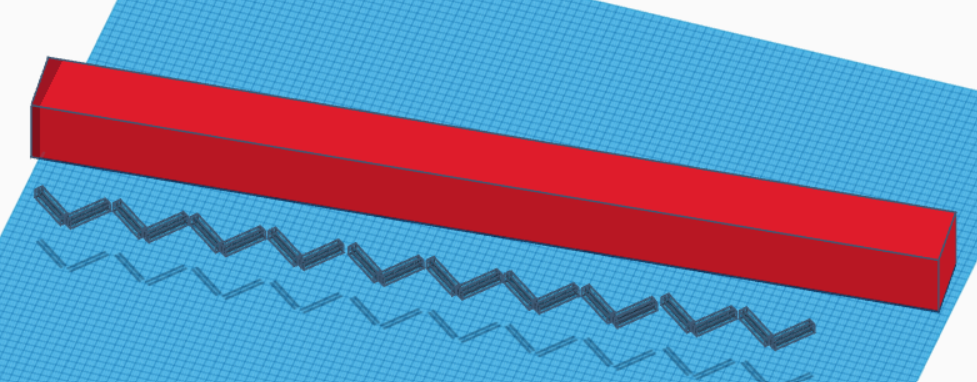

I adjusted the dimensions to what I would eventually like to do. Overall the base would be 1000mm or 1m in length, the width is 75mm, and the depth is 75mm.

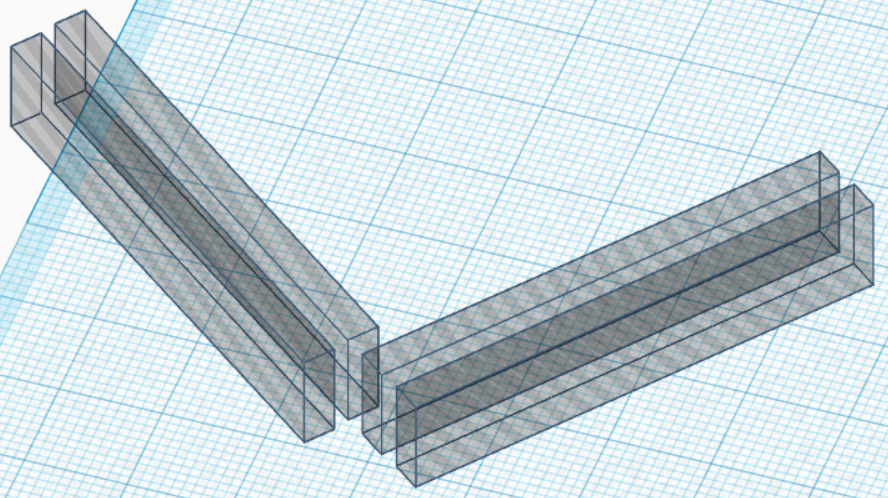

There will be 2 drawings/faces. Each face will be 10 slices and each slice is 50mm by 500mm with a 10mm adjustment to allow for space into the base. A full face will be 500mm by 500mm, so with 2 faces, it will be 500mm by 1000mm. Given that the slices will be placed on an angle, the base is still 1m and will have room to adjust the battery.

I need to move the holes into the base, but I want to create a removable panel to input the circuitry.

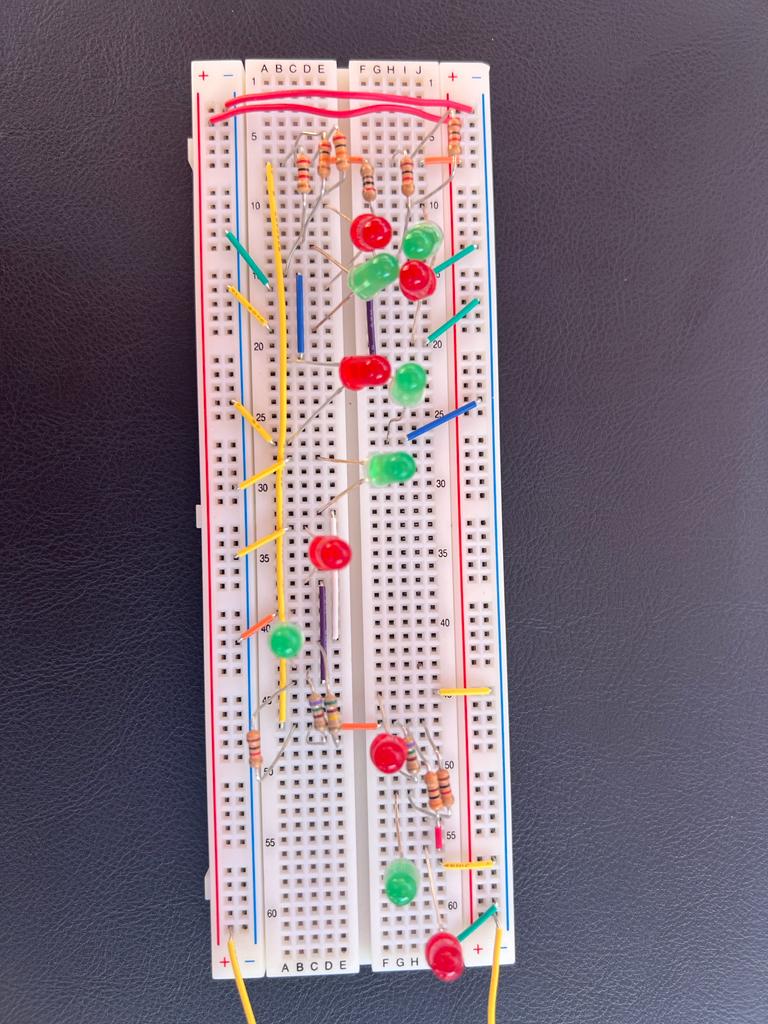

I tried to make a place holder circuit with 12 LEDs in parallel.

Questions:

- I am not very familiar with CAD, so if anyone has any tips to ensure that I am making a panel properly.

- How do I 3d print in parts?

I also placed an order for some supplies:

- better LEDs

- battery

- black acrylic for the backing

- clear acrylic

- circuit board to solder onto

I know that you want to learn about 3D modeling but I do think laser cutting would be a much more efficient mode of manufacturing the parts you want. You can always make a 3D model of the whole system to check tolerances and make sure it will fit together, and then laser cut the individual parts.