This week I have been making progress on my final installation. It is not fully functioning yet. I am currently finishing up the mechanical build before moving on to the wiring of the LEDs. Currently I have a polycarbonate sheet that I am about to drill 500 holes into for each of my LEDs to poke through. I am researching the best way to drill into this material without completely destroying it considering it cost me $50.

I plan to melt a hole for each LED in the ping pong ball using a soldering iron. This will ensure the LED only has to diffuse through one layer of the ping pong ball instead of two. Once the :LED

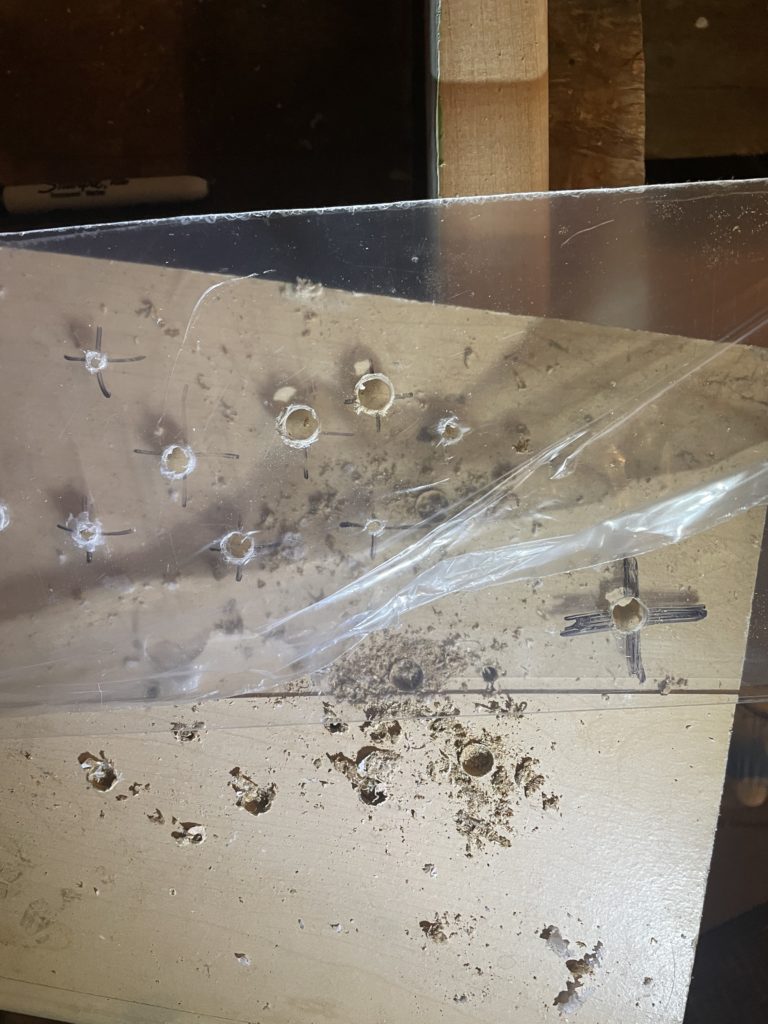

Drilling Into Polycarbonate Trials:

The LED’s are roughly 1/4″ diameter. At first, I tried to drill a smaller pilot hole and then increased the drill bit to 1/4″. That proved to end with cracking the plexiglass so I then tried just starting with the 1/4″ bit. That worked pretty well. I noticed the bit was traveling a little if I wasn’t applying a good amount of pressure into the drill.